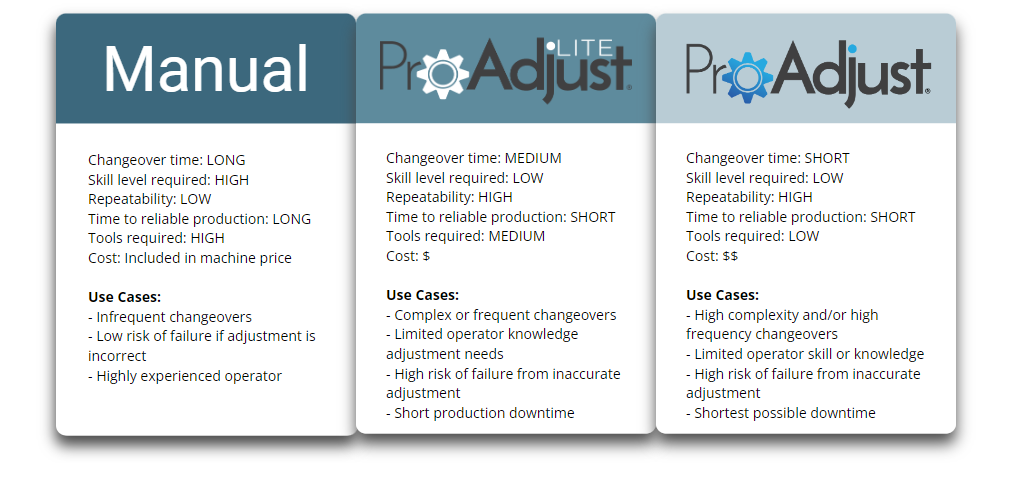

Nearly every modern manufacturer is looking for a way to cut out waste, wasted time…wasted material…wasted inventory…wasted labor. Our range of change adjustment options allows you to select the method that best suits your needs and budget. Ranging from completely manual to fully automated, Schneider has the solution to make changeovers fast and accurately.

ProAdjust® is an automated machine adjustment system featuring an easy-to-use hand-held interface driving power modules which make the adjustments.

Nearly every modern manufacturer is looking for a way to cut out waste, wasted time…wasted material…wasted inventory…wasted labor. ProAdjust minimizes your waste.

What is the best way to reduce changeover and machine setup?

For example, a soft drink manufacturer wants to change their bottling line from 20 ounce bottles to 2 liter bottles.

The number of adjustments are so great, changing over the machine is not cost feasible.

Instead of adding a new production line, can we utilize existing pieces of equipment at 100%?

Life expectancy of a machine can be over 20 years and a large investment for most companies.

ProAdjust Installation Guide »

With more than 50 years of industry problem solving in end-of-line automation, Schneider Packaging Equipment Company, Inc. is a leading manufacturer of case packing and robotic palletizing solutions. Headquartered in Upstate New York, we design state-of-the-art machinery for customers in industries such as food and beverage, dairy, pharmaceutical, personal care, plastics, and paper.

© 2021 Schneider Packaging Equipment Company, Inc. | Privacy Policy